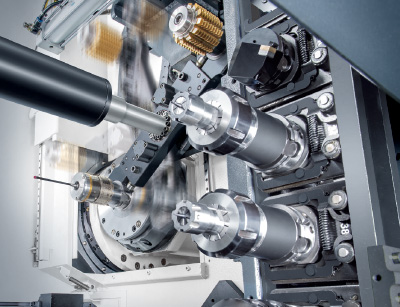

HIGH EFFICIENCY AUTOMATIC TOOL CHANGE SYSTEM

The chain type magazine is combined with the design of the arm type automatic tool change system, which has ample tool positions, fast and reliable tool change, can significantly save non-cutting time, and can meet the processing needs of complex workpieces

- The tool magazine and the control panel are both installed on the front of the machine, making it easier and safer to disassemble and assemble tools.

- The protective door of the tool magazine is equipped with a large window, providing a high degree of visibility.

Arm type automatic tool change system

Arm type automatic tool change system

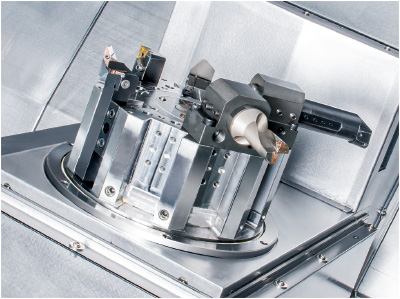

HIGH RIGIDITY LOWER TURRET

The lower turret can not only make the process arrangement of the GMT-2000 series more flexible, but also can install alternative equipment such as live center, steady rest, workpiece support, etc., which greatly improves the processing efficiency.

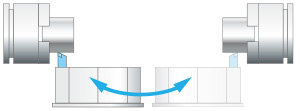

Single tool supports twin spindlesThe lower turret can use the same tool to support the spindle 1 and spindle 2 respectively, which can reduce the number of machining tools required and make the tool position of the turret more flexible.

9-station lower turret ( 25 / Ø 40 mm )

9-station lower turret ( 25 / Ø 40 mm )

In addition to using the tailstock, you can also use the lower turret to install a live center for workpiece support, which has the advantages of smaller interference and higher work efficiency.

The steady rest installed in the lower turret can provide stable support rigidity for long workpieces and reduce the rotation deflection error. The steady rest can be automatically centered, and the workpiece can be directly processed after clamping.

![[x]](../../../../images/turning/multi-axis/gmt/tooling/live-torque.jpg)