HIGH PERFORMANCE MILLING SPINDLE

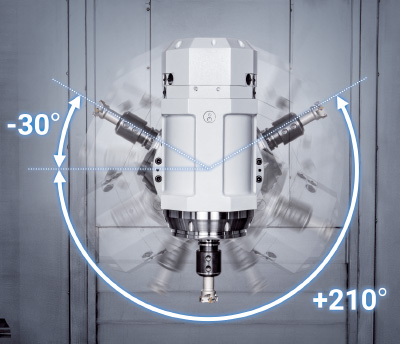

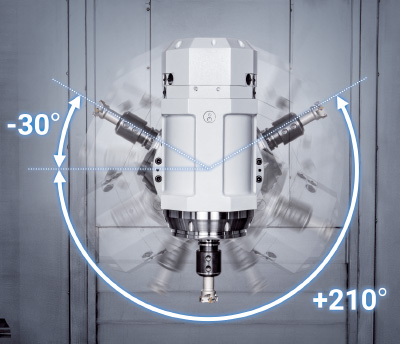

The milling spindle comes with many features such as high speed, high horsepower, low interference, etc.; it can continuously index every 0.0001° within the 240° B-axis travel range. Not only to perform heavy cutting on fixed angle, but also perform 5-axis simultaneous motion contour milling, with extremely flexible processing capabilities.

Modular Design

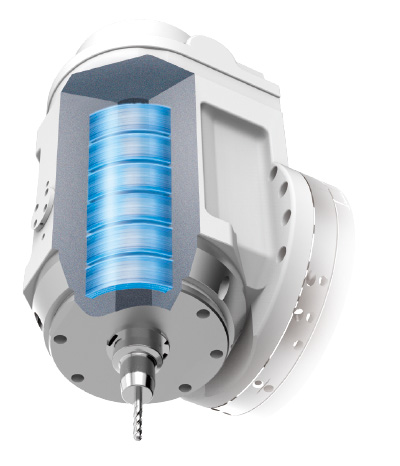

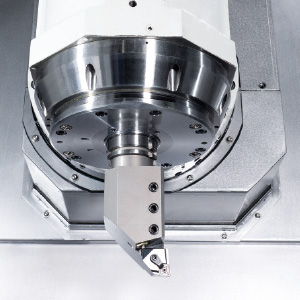

The milling spindle is composed of three core components, spindle, B-axis and interface connector. The signal line between the components and the air hydraulic pipeline are connected by modular connectors, so there is no need to disassemble the line for maintenance. Significantly reduces downtime for maintenance.

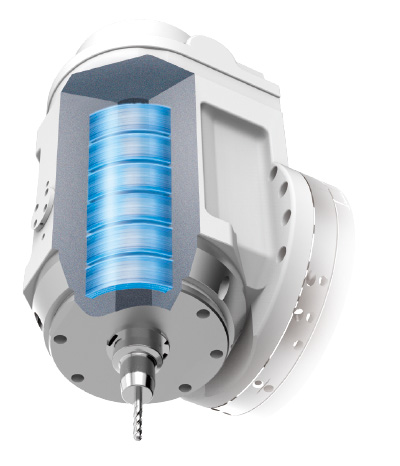

High Precision Built-in Spindle

The built-in motor design can reduce the rotation vibration of the spindle, extend the life of the spindle, and ensure processing accuracy under long-term operation.

The special labyrinth structure design allows the spindle to have an excellent protective effect. Even if the high-pressure cooling system is used for cutting, the coolant will not pollute the spindle. ( CTS function is option )

Cooling Oil Circulates

The cooling circuit circulates around the spindle shaft and front bearing, and the temperature is precisely controlled by an independent cooler which can effectively reduce the thermal displacement of the spindle and ensure excellent machining accuracy.

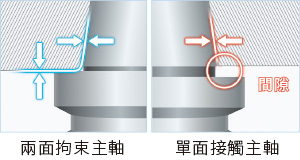

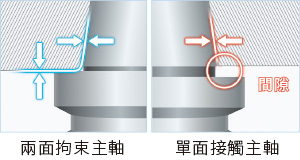

The taper surface and both ends of the two-sided fixed beam spindle can be closely attached to the tool holder at the same time, ensuring the required tool blades under heavy cutting conditions and extending the tool. ( HSK-T63 and Capto C6 are available. )

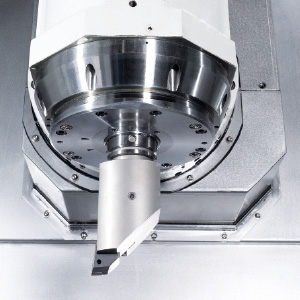

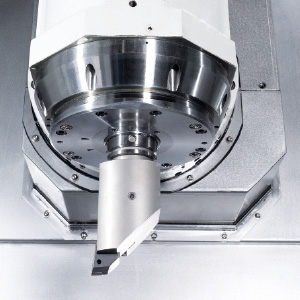

High Rigidity B-axis

High rigidity roller cam transmission design, not only the anti-torque capacity is up to 970 Nm, but also the rotation accuracy is high, the backlash is almost zero, and the minimum indexing of the B axis is 0.0001° ( Standard function

fully closed loop rotating optical scale )

The braking system adopts a hydraulic brake combined with a 3-piece curvic couplings design, with a clamping force of up to 3,000 Nm, which can meet the machining rigidity required for heavy cutting at a fixed angle.

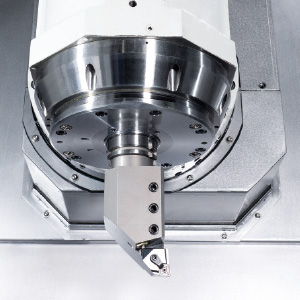

Through the rotation and positioning of the milling spindle, the same turning tool can support the first and second spindles, which can reduce the number of tools required, eliminate the time for tool exchange, and improve production efficiency.

Home

MULTI-AXIS TURNING

GMT Series

Overview

Performance

Milling-spindle

Tooling

Equip

Specifications

Dealer Network

Contact / Inquiry

![[x]](../../../../images/turning/multi-axis/gmt/milling-spindle/torque.jpg)