THE ULTIMATE MACHINING POWER

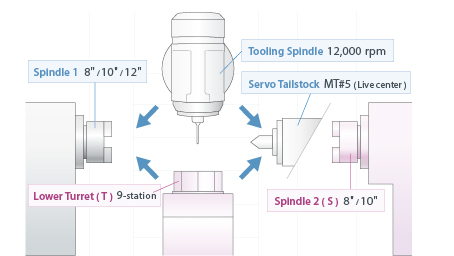

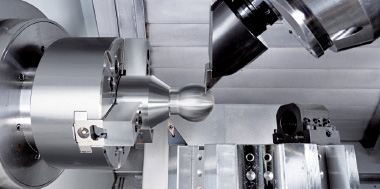

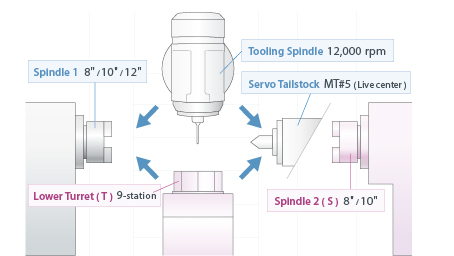

Both the milling spindle and the lower turret can flexibly support the spindle 1 or the spindle 2, making the process arrangement more flexible than more general models. In addition, the long and slender bar is clamped and fixed at both

ends of the twin spindles. The milling spindle and the lower turret are synchronized to balance cutting, which can greatly shorten the cycle time and ensure the ultimate machining accuracy.

| Model |

GMT-2000 |

GMT-2000S |

GMT-2000ST |

| Max. turning length |

1,020* / 1,520 ( L1 ) / 2,520 ( L2 ) mm |

| Max. turning diameter |

Milling-spindle |

Ø 660 mm |

| Lower turret |

— |

— |

Ø 420 mm |

| Milling spindle |

● |

● |

● |

| Spindle 1 |

● |

● |

● |

| Servo tailstock |

● |

— |

— |

| Spindle 2 |

— |

● |

● |

| Lower turret |

— |

— |

● |

* GMT-2000ST does not provide this specification.

● : Standard —:Not Available

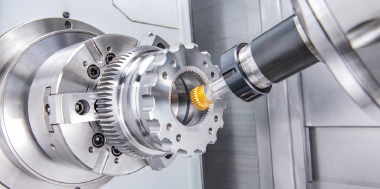

5-axis simultaneous milling

5-axis simultaneous milling

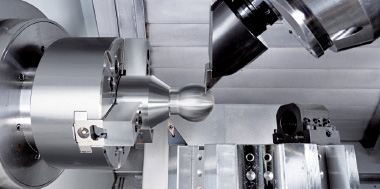

Balance cutting

Balance cutting

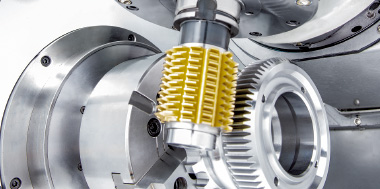

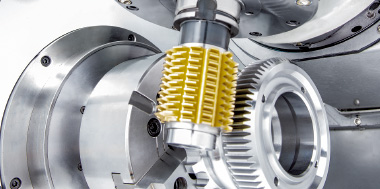

Gear hobbing

Gear hobbing

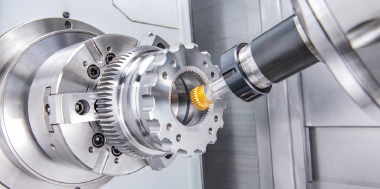

Skiving

Skiving

Simultaneous processing

Simultaneous processing

Flash tool ( multi-blade )

Flash tool ( multi-blade )

Significant Production Efficiency

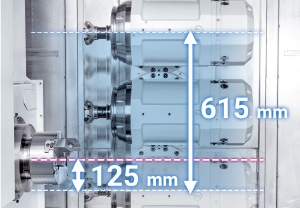

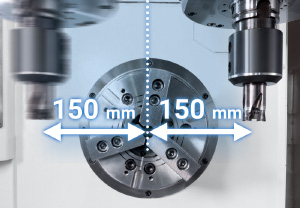

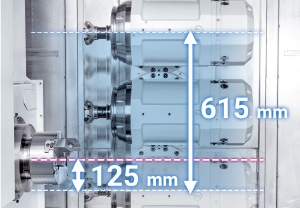

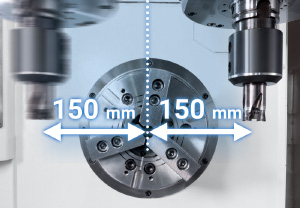

Since the maximum stroke of the X-axis can exceed the centerline of the spindle by 125 mm, and the maximum stroke of the Y-axis is ±150 mm from spindle center, the GMT series can perform high-precision contour milling and drilling even

if it is not controlled by the C-axis, and the processing is more efficient.

The three-axis feed system, including the X, Y, and Z axes, are directly driven by a high-load servo motor with a rapid feed rate of up to 50 / 40 / 50 m/min.

Sufficient Processing Range

The X, Y, and Z axes maximum stroke leads all other models of the same class, making processing more flexible.

3 different lengths of machine beds with 3 different spindle specification providing 9 basic specification combinations.

A chain type tool magazine with up to 120 tools can be installed to easily overcome any complex cutting tasks.

High-precision Countermeasures

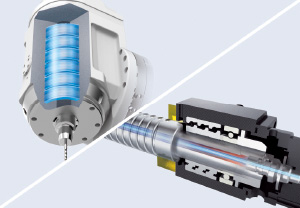

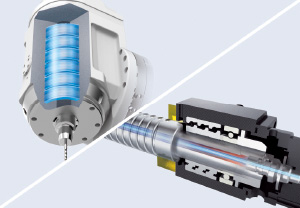

The spindle, milling spindle and feed system are equipped with cooling circuit design, which can effectively inhibit thermal displacement and ensure the ultimate machining accuracy. *1

B-axis standard high-resolution rotating linear scale.

Optional spindle thermal compensation system.

*1 : The X1-axis is equipped with a hollow ball screw as standard, other axial options are available.

X-axis travel

Y-axis travel

Cooling Technology

X-axis travel

Y-axis travel

Cooling Technology

Home

MULTI-AXIS TURNING

GMT Series

Dealer Network

Contact / Inquiry

5-axis simultaneous milling

5-axis simultaneous milling

Balance cutting

Balance cutting

Gear hobbing

Gear hobbing

Skiving

Skiving

Simultaneous processing

Simultaneous processing

Flash tool ( multi-blade )

Flash tool ( multi-blade )

X-axis travel

Y-axis travel

Cooling Technology

X-axis travel

Y-axis travel

Cooling Technology