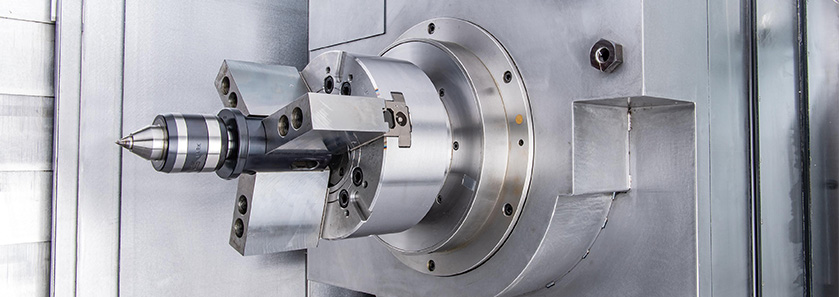

HIGH RIGIDITY SERVO TAILSTOCK

The servo can provide sufficient support rigidity for long shaft workpieces, avoid workpiece rotation yaw errors, and meet high-precision machining requirements.

- Through M code control, the tailstock servo motor and ball screw drive to the desired position, without manual adjustment, it can easily and quickly withstand the center of the workpiece.

- Through the powerful thrust of the servo motor, the tailstock can hold the workpiece firmly and continuously to ensure the supporting rigidity required during heavy cutting.

- The models equipped with the spindle 2 ( GMT-2000S / GMT-2000ST ) can also use the clamping jaws to install the live center, which has the function of a servo tailstock.

| Model | GMT-2000 series |

|---|---|

| Tailstock type | Programmable servo tailstock |

| Quill center taper | MT#5 Live center |

| Quill diameter | Ø110 mm |

| Tailstock base travel | 1,560 mm |

OUTSTANDING OPERABILITY

The pneumatic unit is equipped on the side of machine for checking and maintaining in time.

The tool magazine is located in front of machine for quick tool mounting / dismounting.

Working Area

The compact designs not only accomplish the optimized working area but provide more convenient and safer loading work.

The control panel can be rotated 310° and left-right move 900 mm according to operator’s requirement.

Roll-out coolant tank with front pulled-designed is easier for operator to clean and maintain.

STRATEGY FOR CHIPS REMOVING

GMT-2000 series comes with a complete strategy for removing chips. It can provide optimized coolant ability for tools and ensure maximum efficiency in removing chips from the machining area. While ensuring the machining accuracy, it also provides the effect of extending tool lifetime.

* Above functions can be chose as optional accessories

Chip Conveyor

Chip Conveyor

Goodway provides the best solution for the chip conveyor according to different type of chips. Chain-belt type chip conveyor is suitable for curled chips. Scrape type chip conveyor is suitable for the powder chips of casting, aluminum and copper.

| Chip type | Curled chips | ||

|---|---|---|---|

| Chip material | Steel | aluminum | color metal |

| Chain belt type | ● | ● | ● |

| Scrape type | — | — | — |

| Chip type | Powder chips | |||

|---|---|---|---|---|

| Chip material | casting | aluminum | copper | non-metal |

| Chain belt type | — | — | — | ● |

| Scrape type | ● | ● | ● | — |

● Applicable —Not applicable