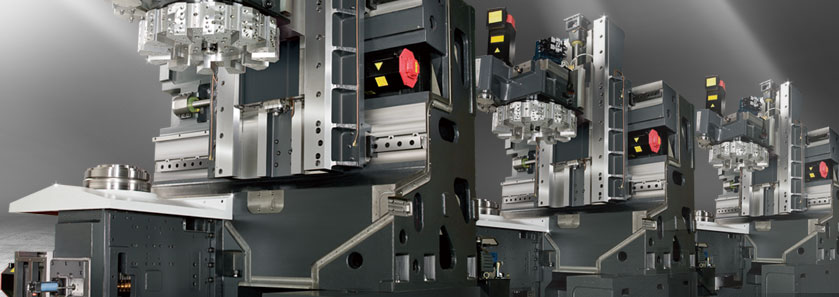

HIGH RIGID CONSTRUCTION

The base and column construction has been made by computer generated design which has increased the stability by 30% over traditional design.

Meehanite grade castings, rib and reinforced provide excellent stability, good thermal expansion and performance for the vertical column.

FANUC alpha i series AC servo motors are fitted to all axes. The alpha Pi intelligent servo motor with its compact size and super high resolution αi series pulsecoder ( standard 1,000,000/rev ) are the perfect partner in this machine tool.

X & Z axes motors are fitted with absolute encoders thus eliminating the need for reference returning the axis before machining.

Casting of GV-1000 series model shown.

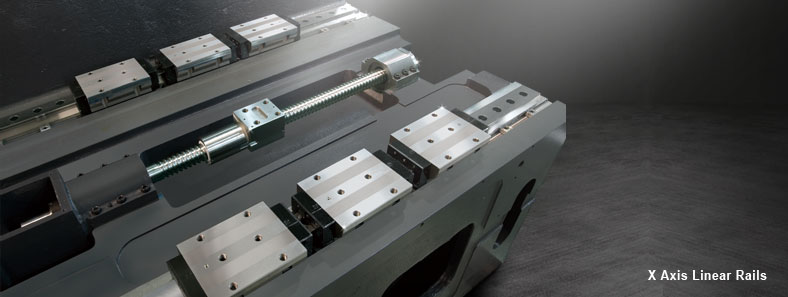

X Axis Linear Rails

X Axis Linear Rails

Japan made linear rails ( roller type ) provide excellent stability in operation.

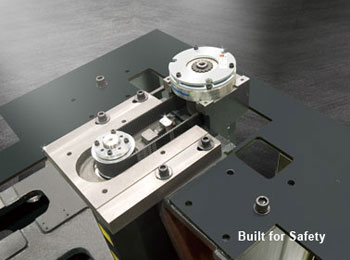

Built for Safety

Built for Safety

The Z axis is fitted with an independent Japan made brake system.

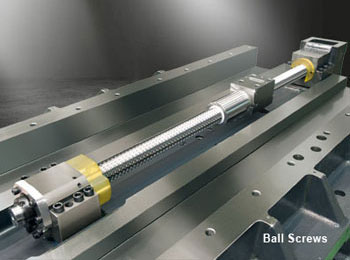

Ball Screws

Ball Screws

C3 class ball screws ( with a pitch accuracy of 12.7µ / 300 mm ) are fitted with pre-load to X and Z axes.

Precision hand scraped

Precision hand scraped

Contact surfaces of all slides, headstock, turret, tailstock, and ball screw bearing housings with the machine bed are hand scraped to provide maximum assembly precision, structural rigidity, and load distribution.