GTH

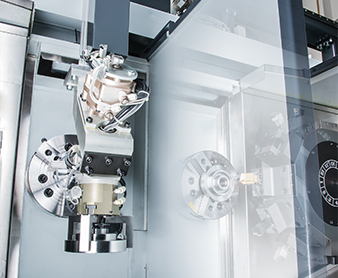

From high efficiency production demand for automobile industry, the GTH series CNC turning center with advanced parallel twin spindles, twin turrets structure and high efficiency automation system, the GTH provides automatic loading, front/rear cutting, unloading and work-piece detecting, which make its ultimate machining capabilities a coordinated process. Furthermore, the GTH series fulfills all types of plate-shape and short-shaft work-piece of automatic mass production needs.

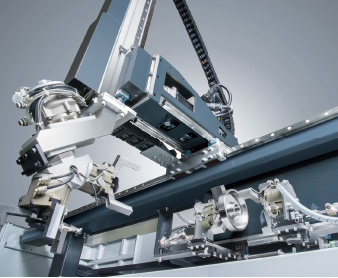

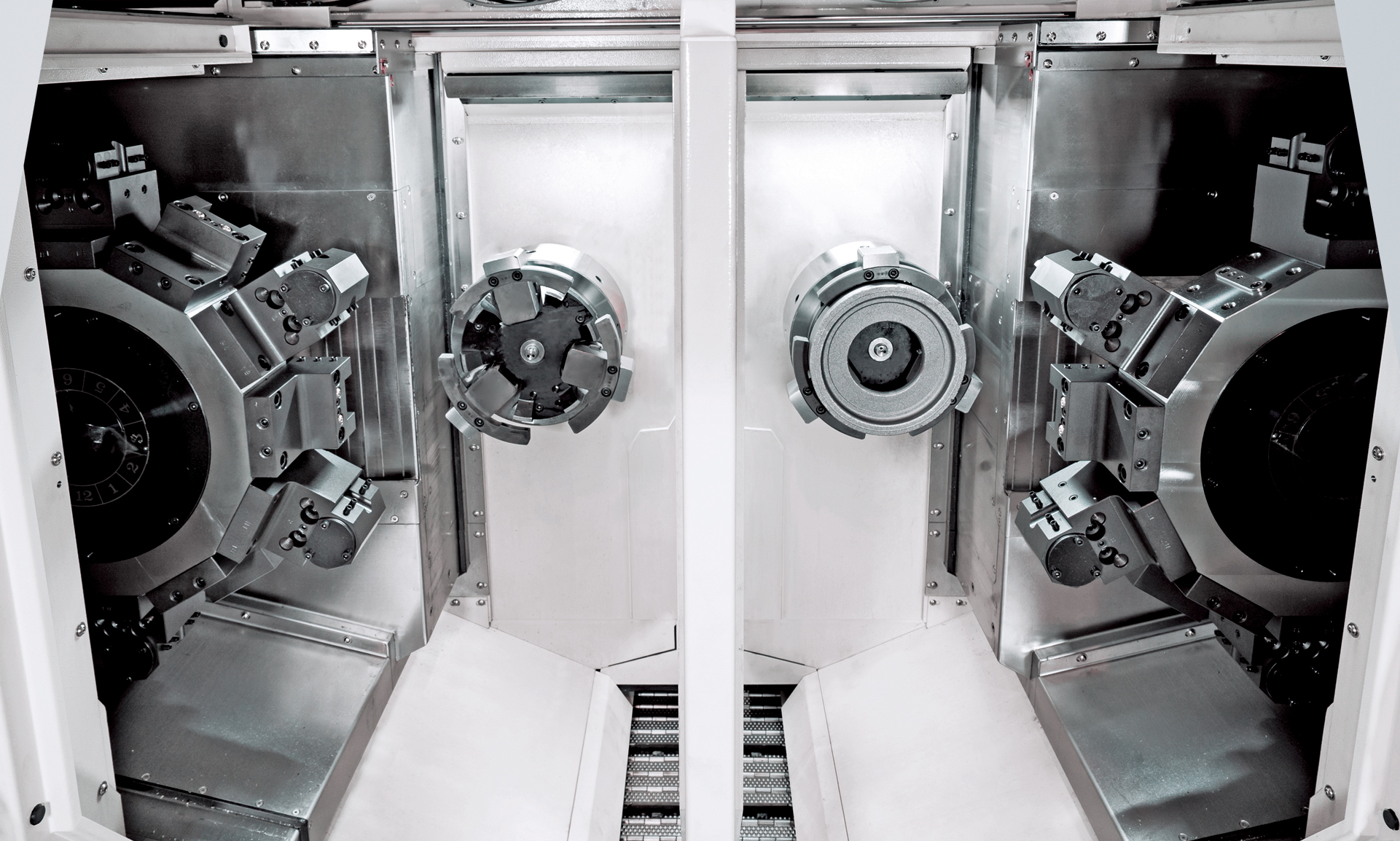

- Parallel twin spindles with twin turrets design; gantry loading/unloading system is standard equipment.

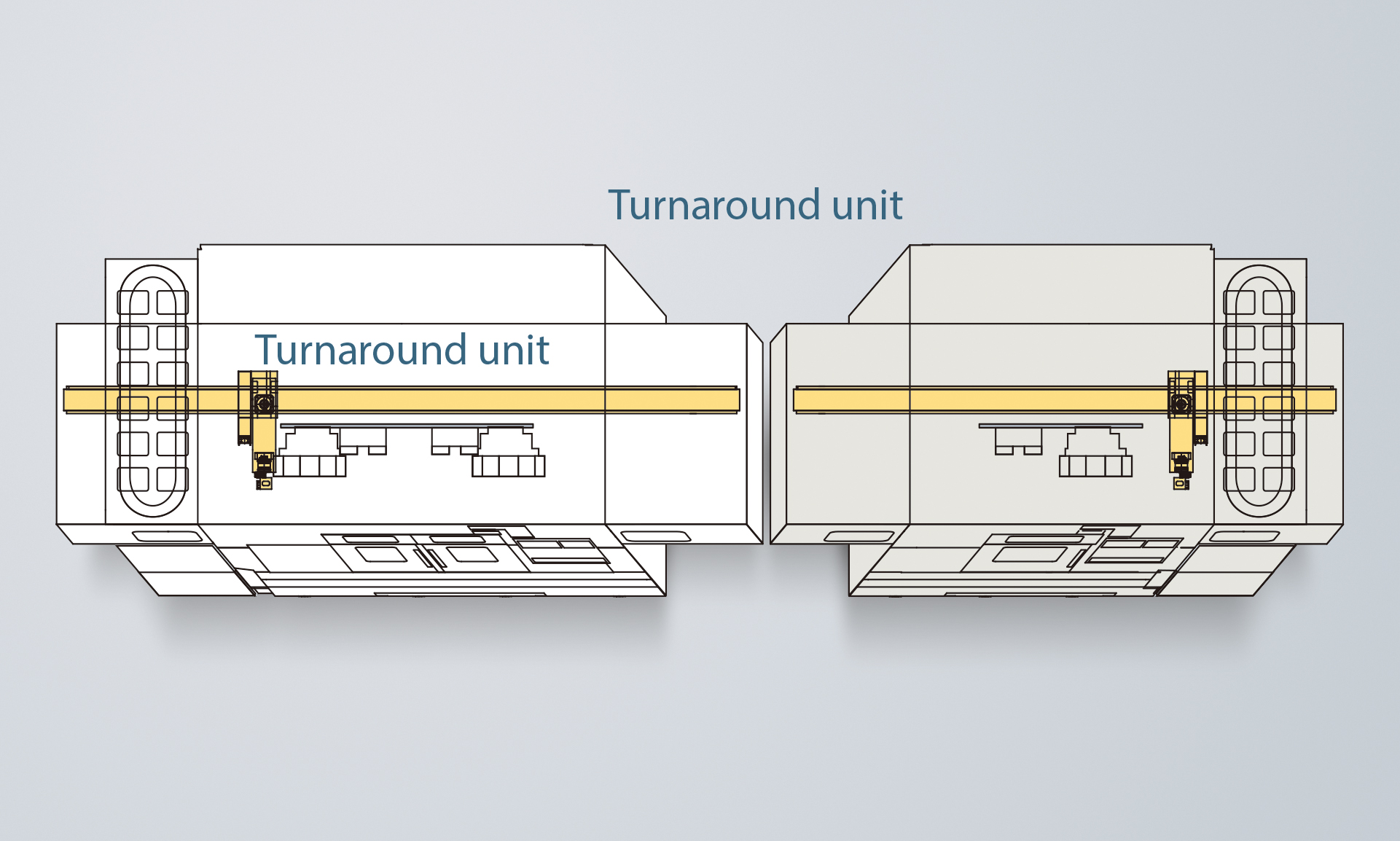

- Easily integrates with multiple GTH series machines or other machining equipment to form a high-efficiency production line.

- Single or twin spindle models available based on actual machining requirements.

- Single and twin spindle models, workpiece flipping device, and gantry robot arm can be flexibly configured into a high-efficiency production line to optimize machining processes.

- Each jaws can hold up to 8 kg of workpiece (subject to actual requirements).

- Disc-type or shaft-type feeding stations available based on material type.

- Optional GOODWAY precision inspection system (non-contact) significantly improves yield detection efficiency.

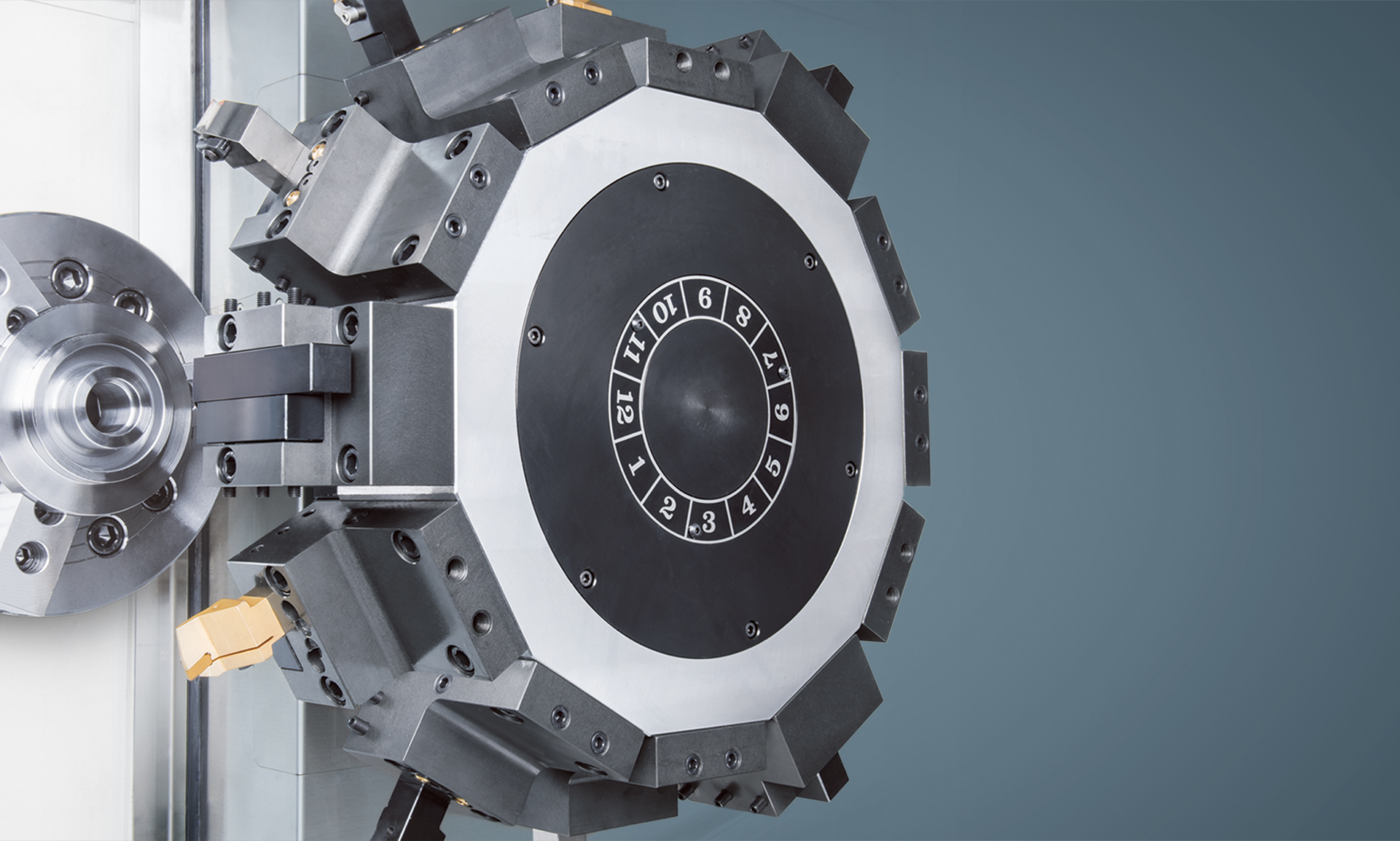

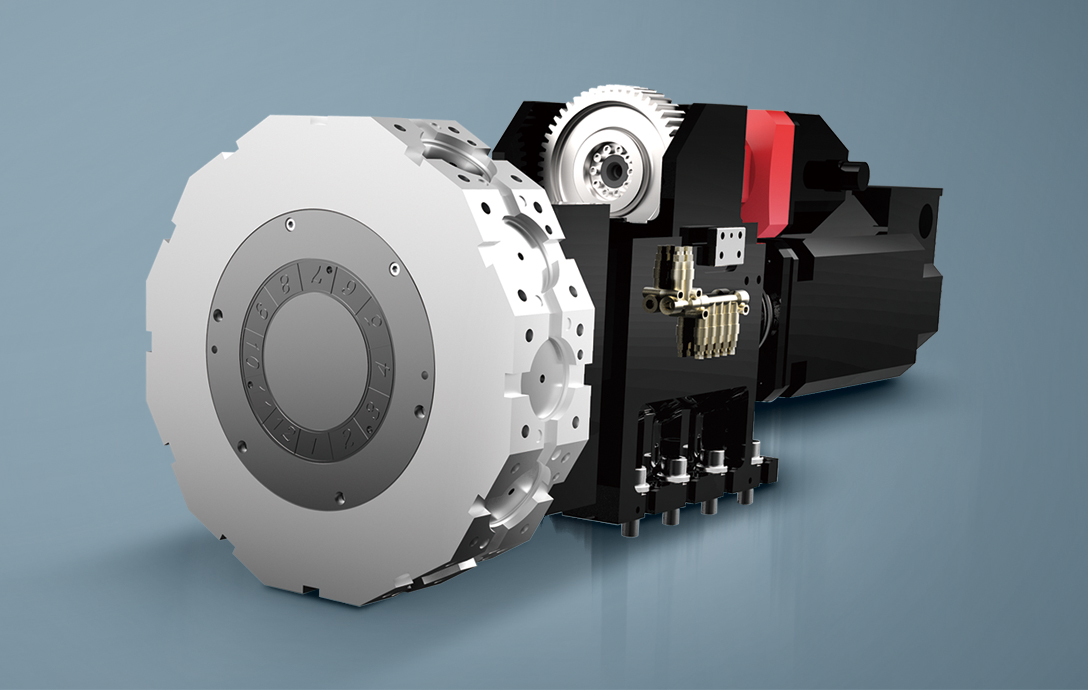

- The 12-station servo turret enables rapid tool changes and delivers outstanding cutting rigidity for high-performance cutting.

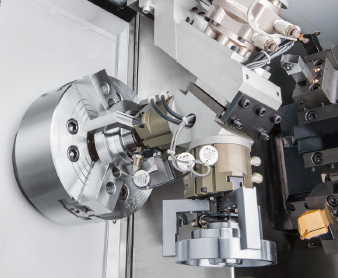

- The spindle is driven by a high-power FANUC motor, with a maximum speed of 4,000 rpm (GTH-2000) / 6,000 rpm (GTH-1500).

Features

Flexible Production Line Configuration

High-efficiency Mass Production Capability

High-performance Spindle and Turret

Model Variations

M

- Live tooling turret

- C-axis

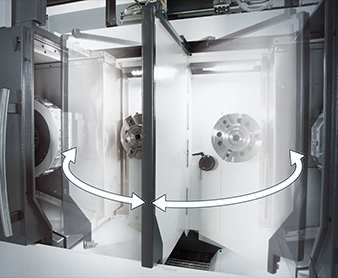

Parallel twin spindles with twin turrets

Rear-exit chip conveyor design

Varies applications

(The illustration shows a single case)

(The illustration shows a single case)

12-station servo turret

Live tooling turret

C-axis

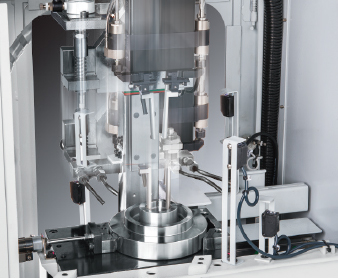

Live Tooling Turret

- The 12-station live tooling turret accommodates 12 live tools, with only the tool at the working position rotating; others remain stationary. (Optional 16-station live tooling turret)

- With the latest technology, live tooling is driven by an AC servo motor to provide ample power, in the form of torque. Now, even the toughest of jobs may be tackled without a sweat.

C-axis

- The FANUC Cf-axis servo motor generating an ultra-high resolution of 33,000,000 pulses per spindle rotation and high output torque, machined surface finishes are much superior. Also, dynamic accuracy is within ± 0.02° even under heavy cutting loads.