GLS-1500

Packed with the latest machine tool technology and rigorous quality verification, the GOODWAY GLS-1500 series high-speed CNC turning center feature a compact footprint and high-rigidity structural design, making them an advanced solution fully capable of meeting high-efficiency mass production demands. Additionally, this series offers optional live tooling turret, C-axis, Y-axis, and sub spindle—features rarely available in similar compact models on the market.

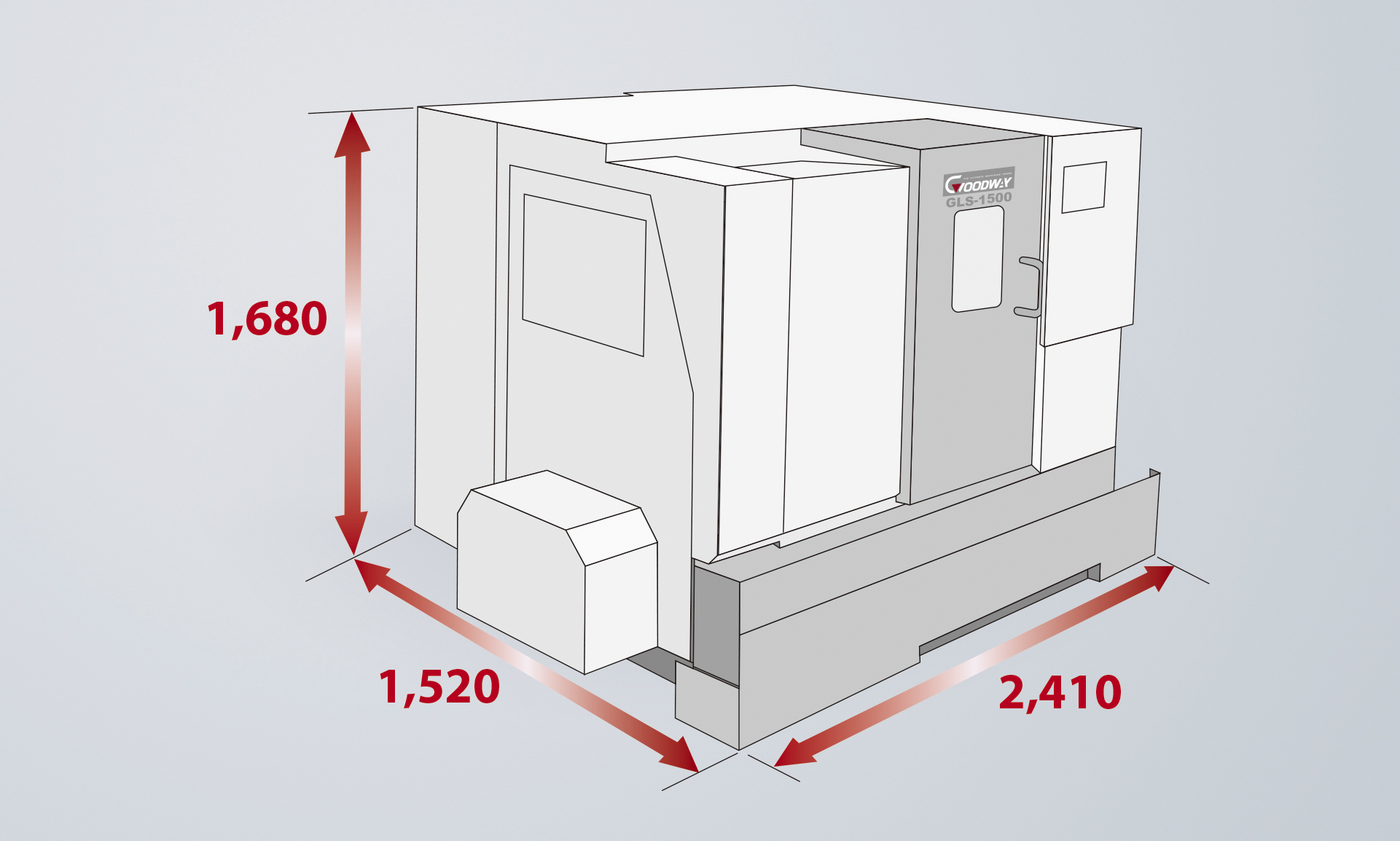

- High-performance slant-bed with linear guideways, occupying only about 4.5 m2 of floor space.

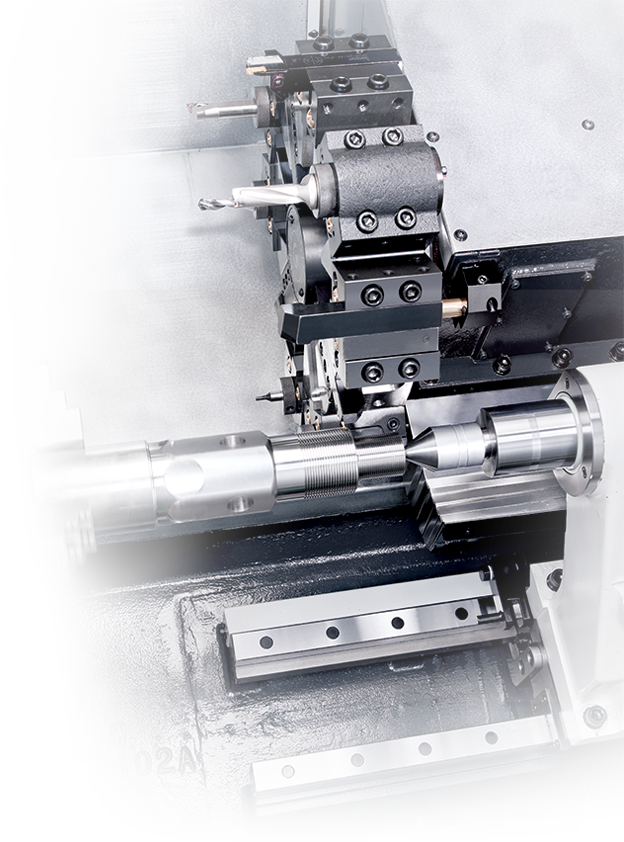

- Comprehensive turning and milling capabilities with a live tooling turret, Y-axis, and sub-spindle.

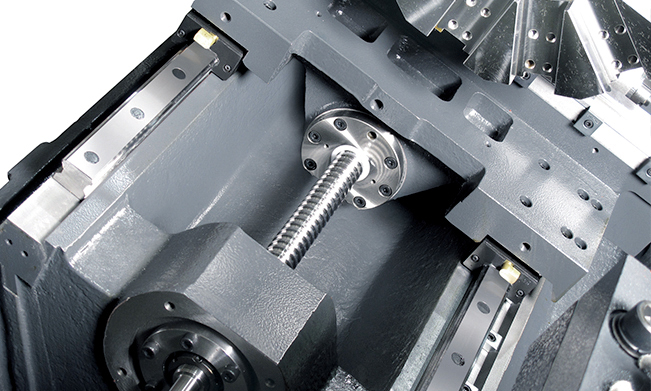

- The low center of gravity 30° slant bed design ensures maximum structural rigidity.

- High precision linear guide way design is used in X and Z axes to provide the optimum control and efficient movement.

- Two-speed motor-driven spindle meets both heavy cutting and precision machining requirements.

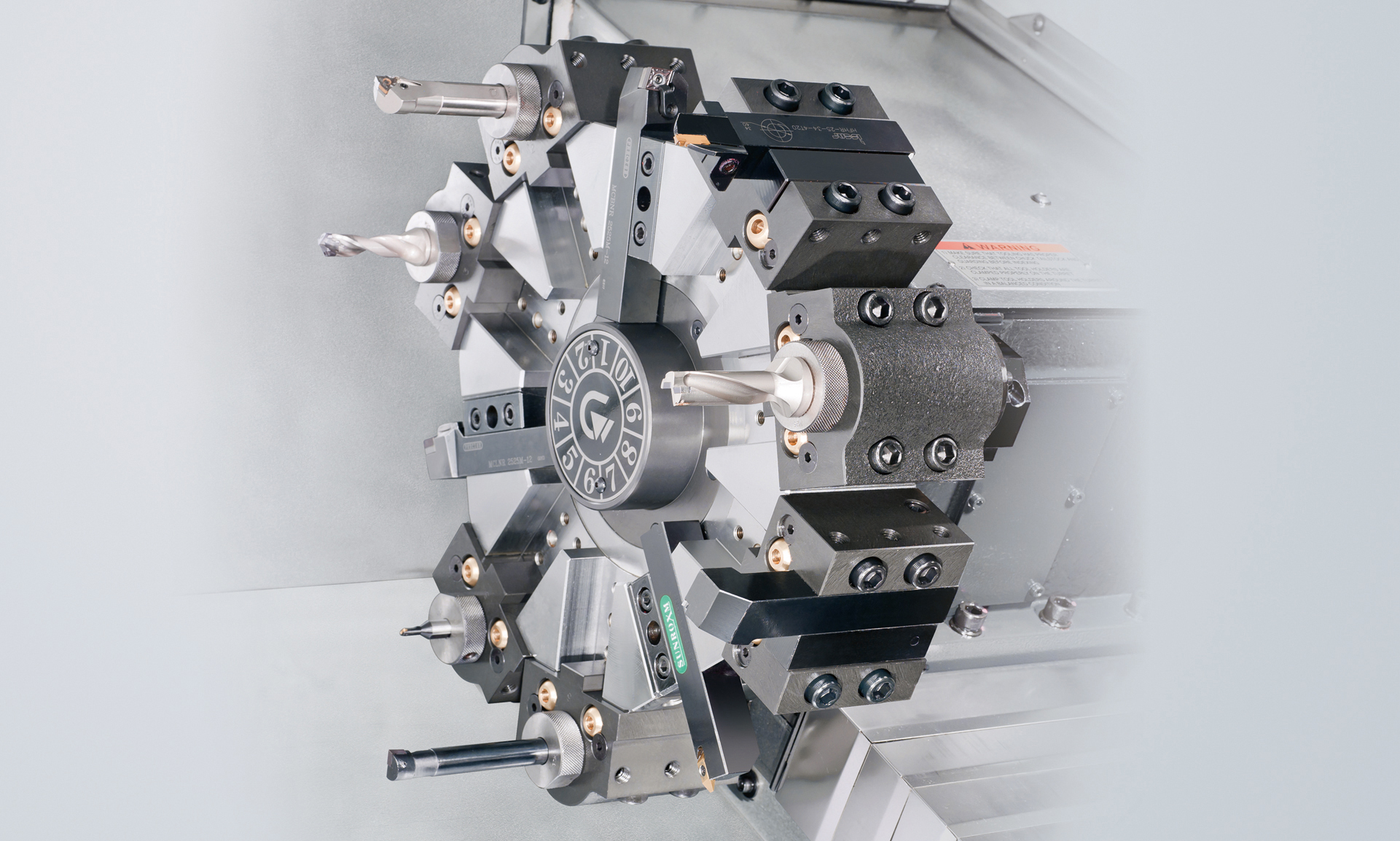

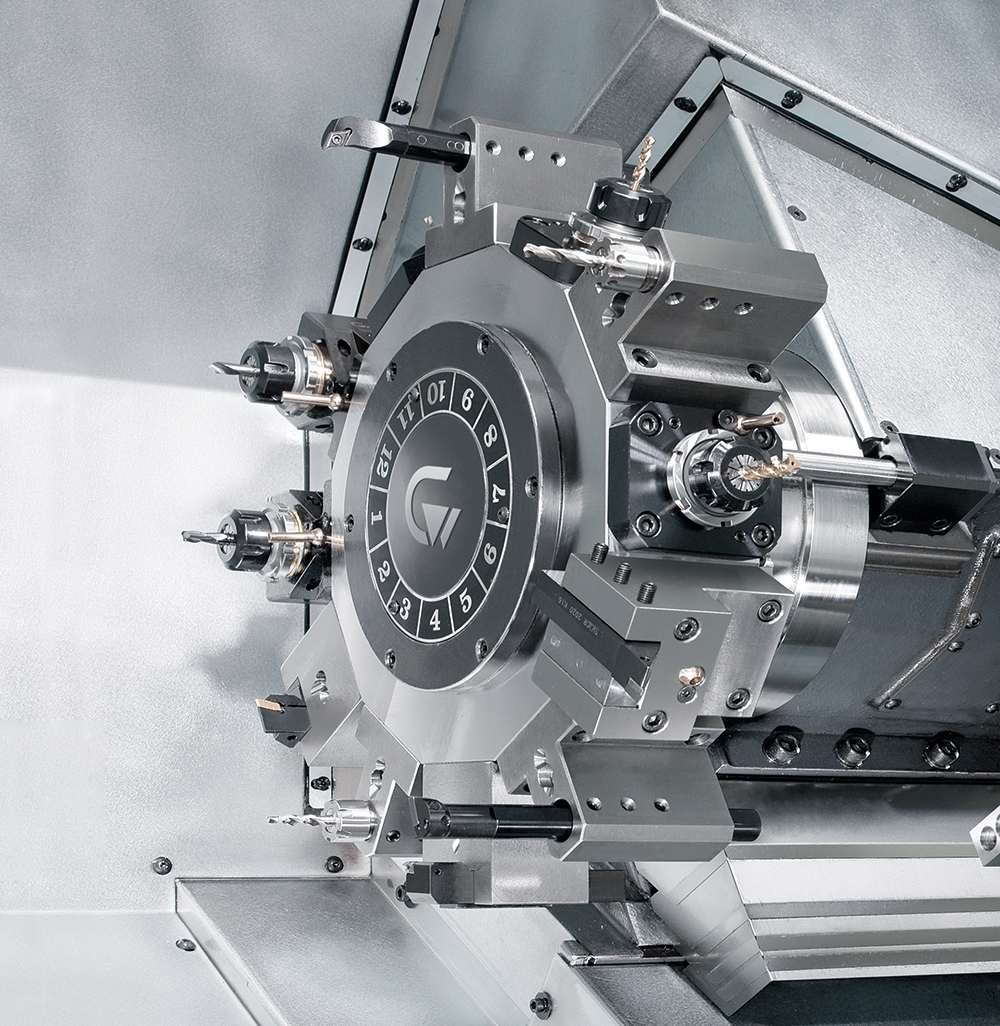

- Versatile configurations with options for 10 / 12 / 24-station turret or gang type tool holders.

- High-efficiency programmable tailstock / High thrust servo tailstock.

- Tailstock can be equipped with MT#4 live center or deep hole drilling tool.

- Optional 12 / 24-station live tooling turret with live tool speed up to 4,000 rpm.

- Sub-spindle equipped with 5" chuck and driven by an built-in type motor, reaching a maximum speed of 6,000 rpm.

- Y-axis control with ±52.5 mm travel enables machining of complex workpieces.

Features

High Rigidity Structure

The Ultimate Machining Power

User-friendly Operation

Integrated Machining

Model Variations

M

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Gang type tool holder

Y

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Gang type tool holder

S

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Gang type tool holder

MS

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Gang type tool holder

YS

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Gang type tool holder

G

- Live tooling turret

- C-axis

- Y-axis

- Sub-spindle

- Gang type tool holder

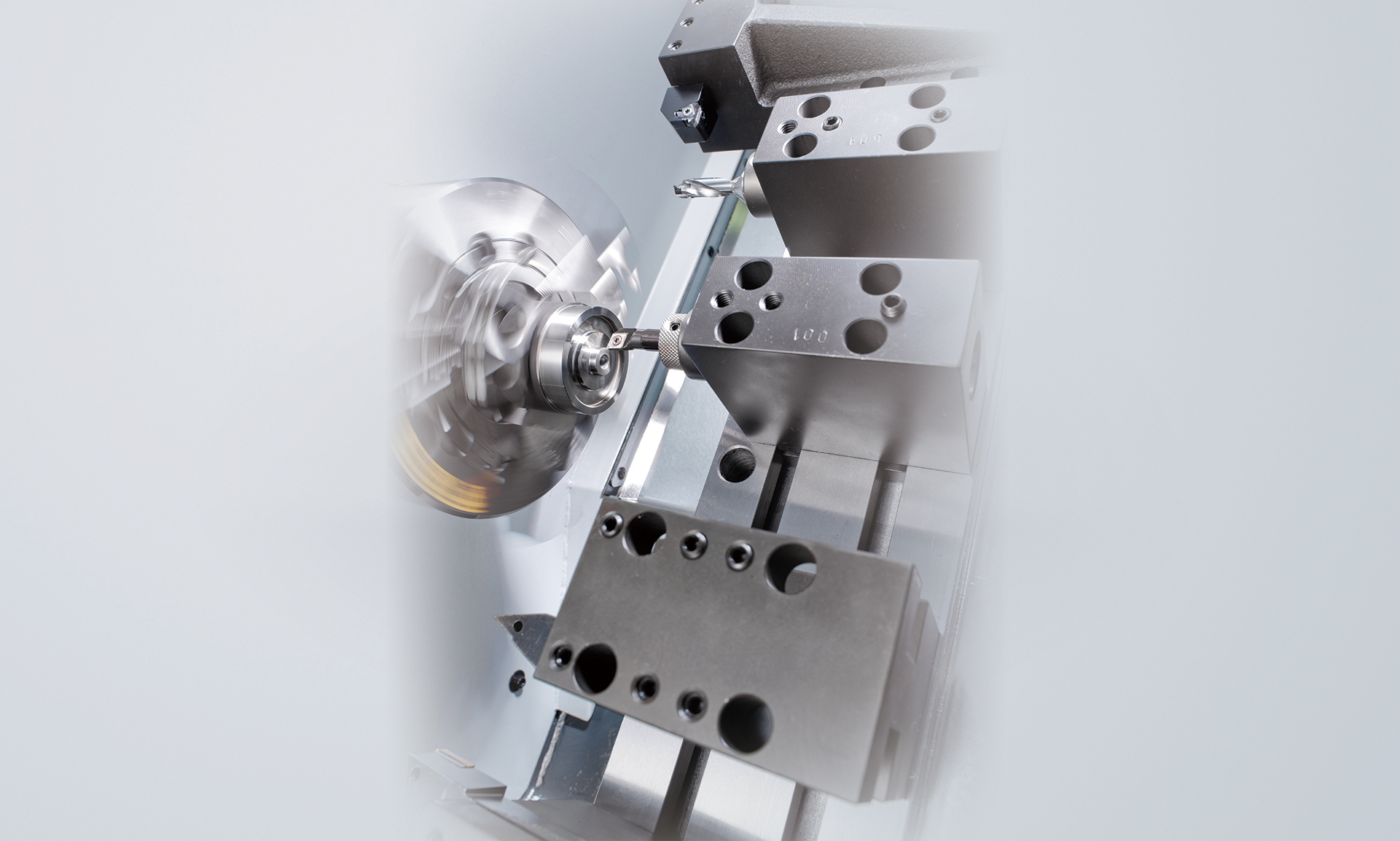

Compact footprint

High-speed linear guideway design

12-station servo turret

Gang type tool holder ( opt. )

Live Tooling Turret

- Live tooling and C-axis control capabilities on the GLS-1500 series allow the machine to perform multiple tasks on a work-piece, such as turning, milling, drilling and tapping. This eliminates manpower and cycle time, while reducing accuracy lost, which will occur if the part is moved from one machine to another.

- GOODWAY live tooling turret utilizes advanced servo indexing technology to achieve 0.2 second indexing time for adjacent stations and 0.5 second for stations at the opposite end of the disk.

- With the latest technology, live tooling is driven by an AC servo motor to provide ample power, in the form of torque. Now, even the toughest of jobs may be tackled without a sweat.

Back Processing Capacity

- A 5" chuck size sub-spindle driven by a powerful 5.5 kW ( 7 HP, 5 min. ) built-in type FANUC motor ( Integrated Motor ) for back-end machining is available on the GLS-1500L series.

Y-axis Control Function

- Y-axis control further enhances multi-tasking live tooling capabilities and improves various machining precision. High precision grooving and X-axis off-center drilling are enabled.