GA

Engineered to handle heavy-duty turning applications with superb accuracy, the GA series ultra performance turning centers combine extremely powerful high torque motors, super rigid box way constructions, and large diameter servo indexing turrets to bring you The Ultimate Machining Power®. The GA series will help you be more competitive by achieving faster cycle times with heavier cuts, faster machine movements, and allow cutting of tough material efficiently. You'll also appreciate the reliability and durability that our machines are known for. Plus, with more standard features than any other machine on the market today, many say it's the best investment they have ever made.

- High cost-performance box-way model.

- Comprehensive automated production solutions.

- The box way design also provides the rigidity needed for heavy duty and interrupted turning applications.

- The precision hand-scraping process ensures the highest assembly accuracy and balanced load distribution.

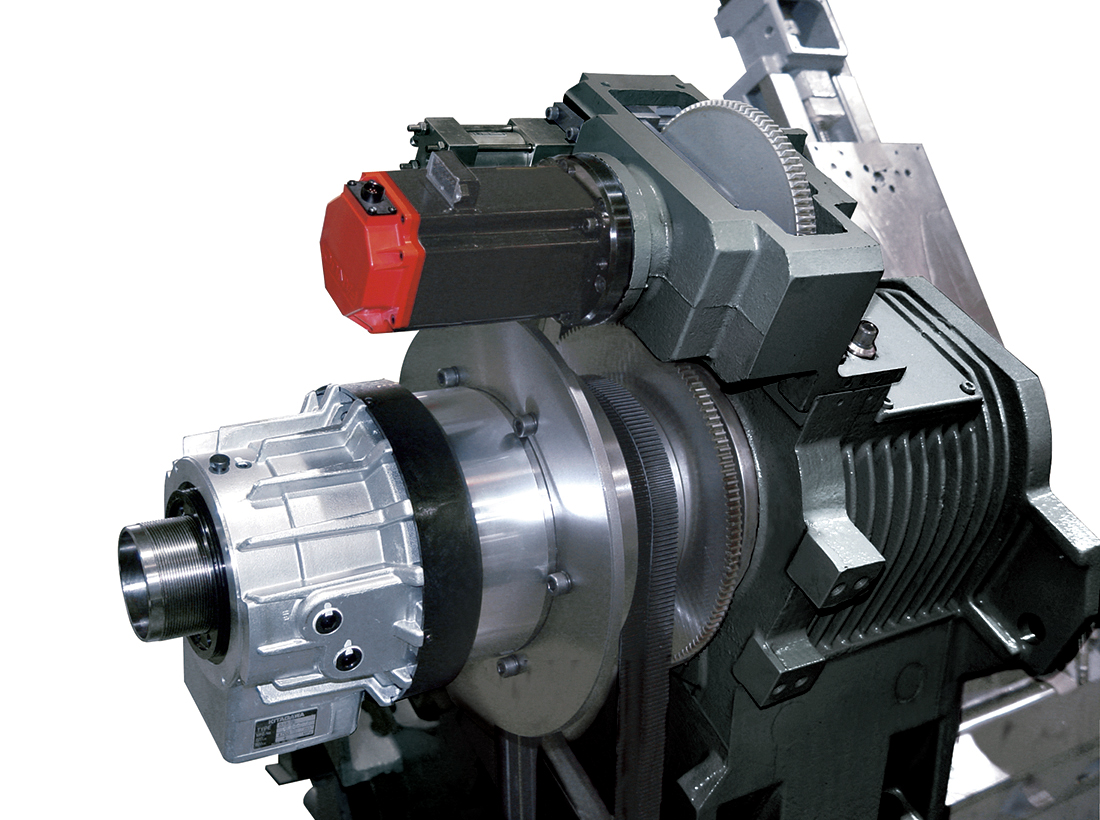

- Spindle system delivers 2.5 to 4 times higher torque than comparable models, offering exceptional heavy-duty cutting performance.

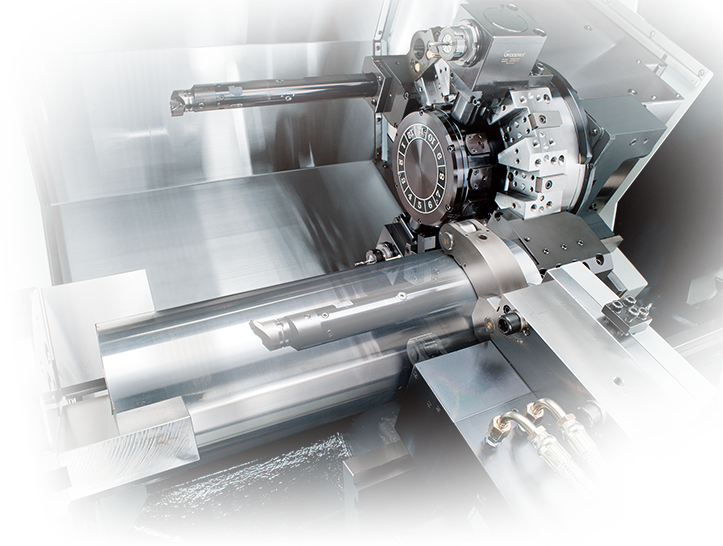

- Heavy-duty 12-station servo indexing turret design; opposing tool change takes only 0.5 seconds.

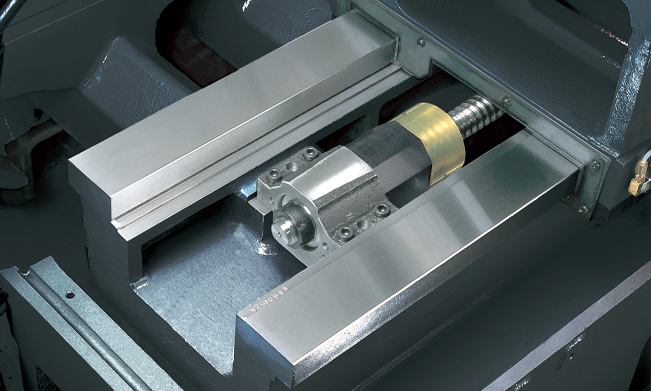

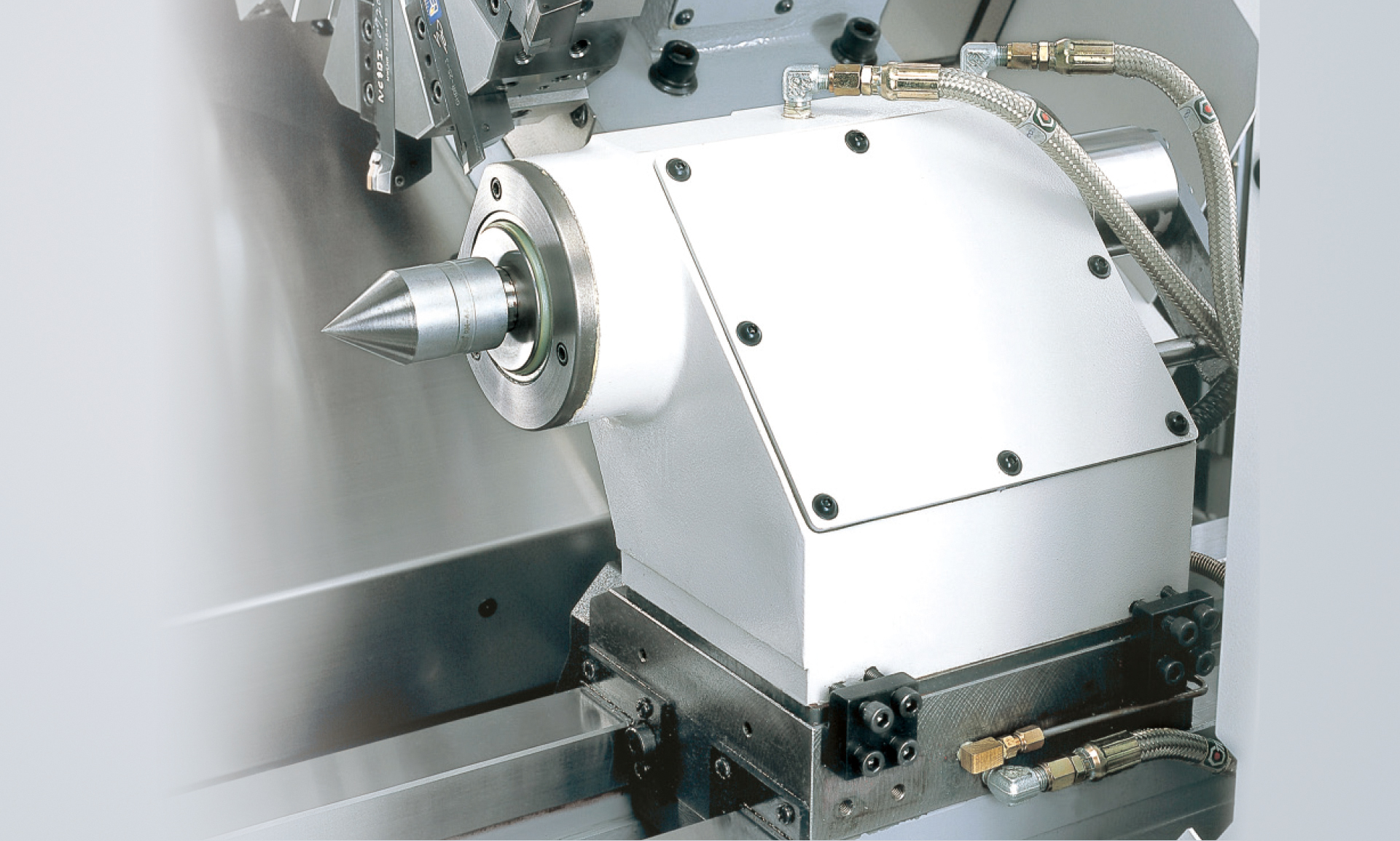

- High-efficiency programmable tailstock.

- Self-centering steady rest.

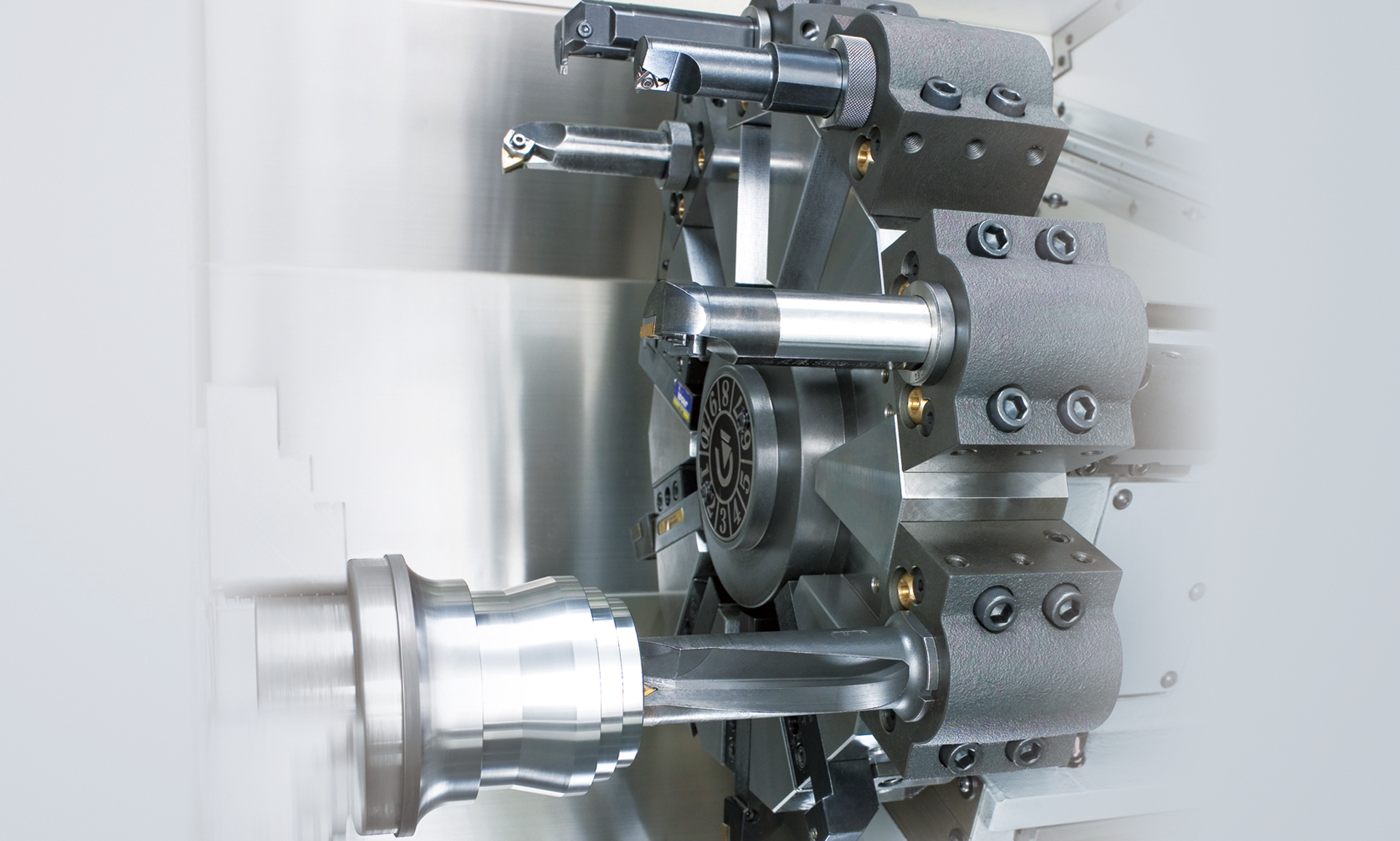

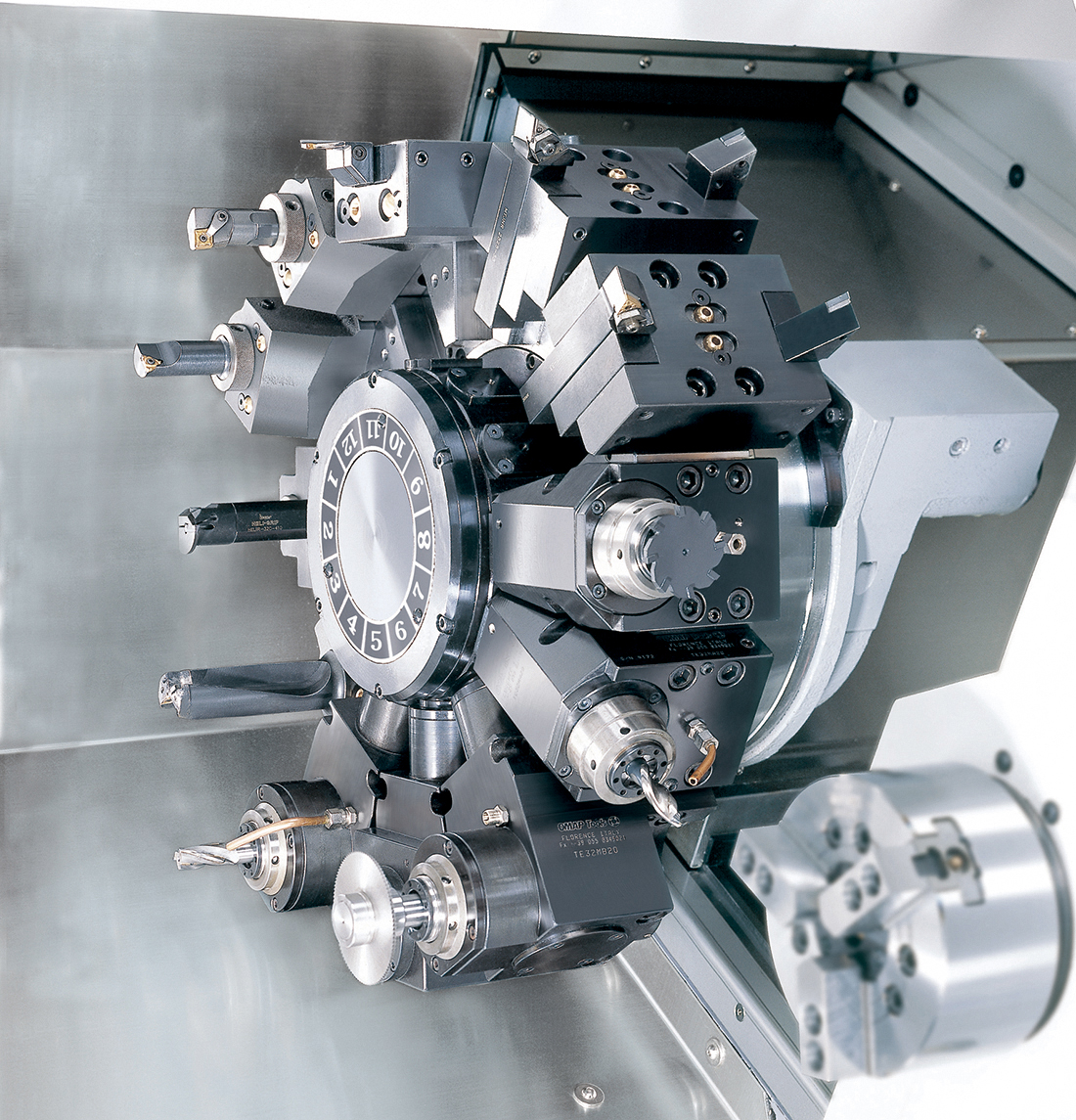

- Optional 12-station live tooling turret is available, with a maximum live tooling speed of up to 4,000 rpm.

- The live tooling turret, combined with GOODWAY live tool holders, delivers exceptional milling performance.

Features

High Rigidity Structure

The Ultimate Machining Power

User-friendly Operation

Integrated Machining

Model Variations

- Live tooling turret

- C-axis

- Y-axis

- Live tooling turret

- C-axis

- Y-axis

Live Tooling Turret

- Live tooling capabilities on the GA series allows a work-piece to be turned, milled, drilled and tapped without moving it to another machine.

- The 12-station GOODWAY live tooling turret offers 12 stations available for live tooling ( live tooling tools rotate in working position only ) and features a non-lifting turret disk.

- GOODWAY's live tooling turret utilizes the latest servo indexing technology to achieve 0.2 second indexing times for adjacent stations and 0.5 second for stations at the opposite end of the disk.

- With the latest technology, live tooling is driven by an AC servo motor to provide ample power, in the form of torque. Now, even the toughest of jobs may be tackled without a sweat.

C-axis

- The Cf-axis and disk brake system available on the GA series provides the most rigid and powerful type of C-axis on the market today. In Cf-axis mode, a servo motor is engaged and drives the rotation of the spindle, engagement time is less than 2 seconds.

- Working with the live tooling turret, the Cf-axis and disk brake system enables the machine to perform drilling, tapping, and milling operations, including cylindrical and polar coordinate interpolations ( resembling a 4th-axis rotary table on a machining center ).

- With the FANUC servo motor generating an ultra high resolution of 33,000,000 pulses per spindle rotation and 480 Nm of torque, surface finishes are much superior than Cs-axis ( driven by spindle motor ) equipped machines. Plus, dynamic accuracy is within ± 0.02° even under heavy cutting loads.